| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Certification : CE ISO SGS

Brand Name : N PACK

Model Number : NP-MFC

Place of Origin : China

MOQ : 1

Price : 9000USD/set to 50000USD/set

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 2000-3000bhp

Delivery Time : 40 working days

Packaging Details : Wooden box

Feed Cylinder Structure : Multi-Room Feeding

Dosing Device : Plunger

Filling Principle : Pressure

Packaging Container Lifting Structure : Pneumatic Lifting

Structure : Rotary

Packaging : Bottle

Packaging Material : Plastic

Bottle Type : Plastic Pet Glass Bottle Jar

Bottle Size : 100ml to 1L

Control : PLC Control

Suitable Product : Cosmetic/Cream/Aste

Filling Heads : 4-20 Filling Nozzles

Transport Package : Wood

Specification : 2m*1.4m*2m

Trademark : Npack

Origin : China

HS Code : 8422301010

After-sales Service : Online Instruction

Warranty : 1 Year

Type : Piston Filling Machine

Automatic Grade : Fully Automatic

Material Type : Paste

Filling Valve Head : Multi-Head

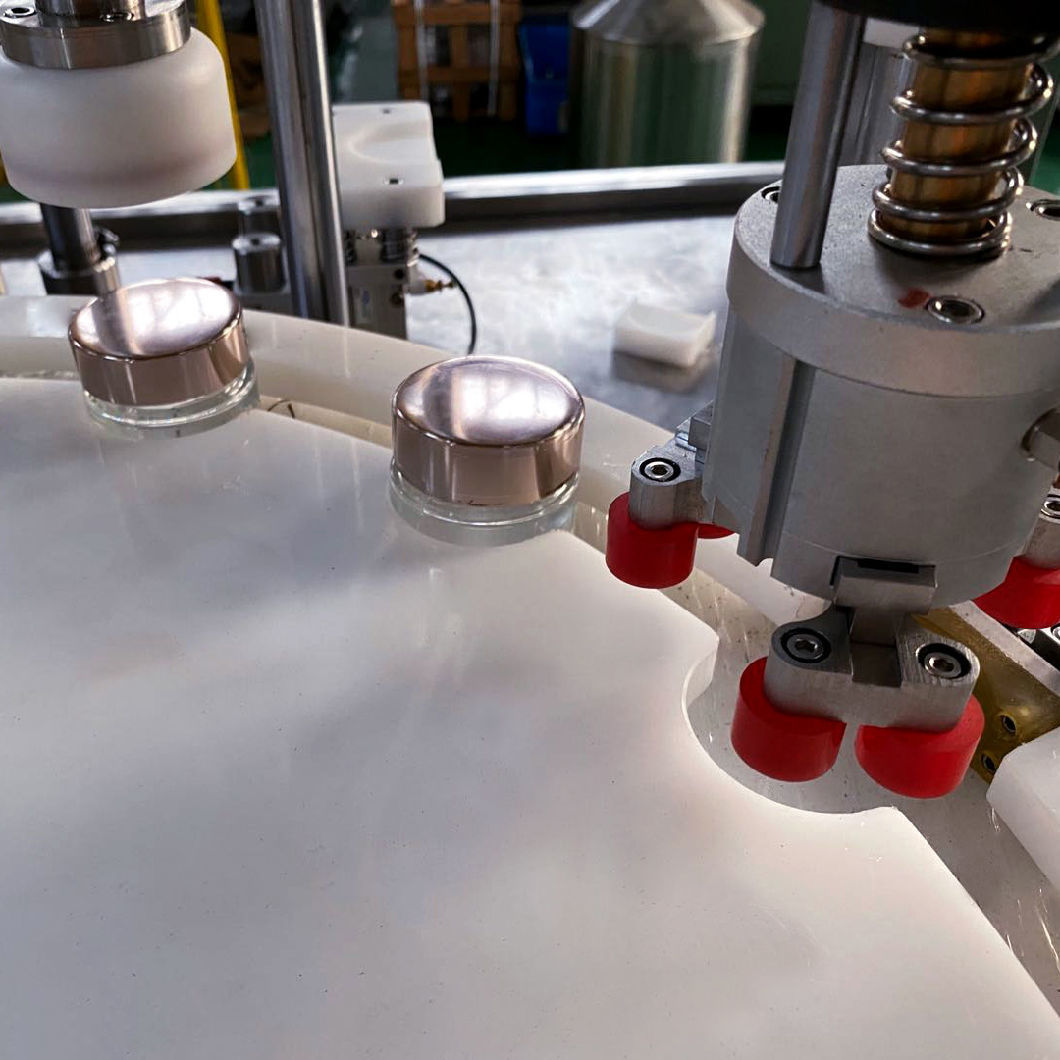

Cosmetic monoblock filling capping machine is equipped with several advanced features to streamline the bottling process. It includes an automatic screw-type bottle feeding mechanism, which ensures a smooth and efficient operation. The system is designed with a bottle detection function that guarantees no filling or cap feeding if a bottle is not present, thus preventing wastage and ensuring accuracy. Additionally, the machine performs automatic filling, cap feeding, and capping, all in a seamless, integrated process. These functions work together to enhance productivity and reliability, making the machine ideal for high-volume production environments.

| Filling speed | 35-40 bottles/min |

| Filling precision | ≥99% |

| Finished product rate of cap drop | ≥99% |

| Main machine power | 1KW 220V stepless shift |

As a specialized manufacturer, NPACK has perfected the design and functionality of its filling and capping machines, setting new standards in the industry. Our machinery is engineered to meet the diverse demands of the processing and packaging sectors, ensuring robust performance and versatility.

NPACK is committed to leading the way in filling and capping technology. We consistently invest in research and development to keep our equipment at the cutting edge of technological advancements. Our team is dedicated to providing exceptional service and support, fostering strong partnerships throughout your experience with us. With a global presence, NPACK is equipped to assist processors and manufacturers worldwide in enhancing their production capabilities, ensuring they remain competitive and efficient.

1. Installation:

Our skilled technicians are available to travel and install your labeling machine. The service fee covers installation, travel, meals, and other related expenses.

2. Training:

To ensure the optimal performance of your labeling machine, we offer on-site or factory training for dealers, machine operators, engineers, and technicians.

3. Guarantee:

We provide prompt repair services for the bottle labeling machine, with a one-year quality assurance period, parts supply, and quick feedback for troubleshooting.

4. Consulting Service:

Take advantage of our free consultation service. Our professional sales team will guide you to the best solution, complete with CAD drawings for your labeling machine.

5. Technical Support:

We offer all-weather, long-term technical support. Simply send us an email or call, and we'll provide quick feedback to ensure peace of mind.

6. Spare Parts:

A set of essential spare parts for the labeling machine is included during transportation at no extra cost. You can also order a full range of high-quality parts at any time.

|

|

Fully Automatic 50g 100g Bottle Jar Cosmetic Cream Mixing Filling Capping Machine Images |